Durable SS304 Woven Wire Mesh for Various Applications

By:Admin

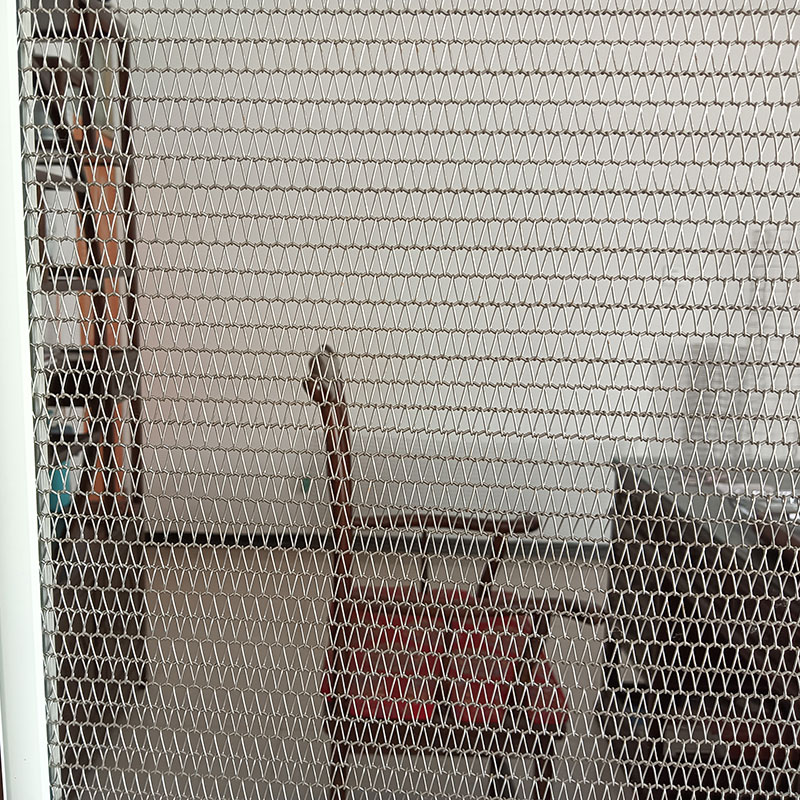

In today's fast-paced world, industries and businesses are constantly looking for innovative solutions to improve their products and processes. One such solution that has been gaining popularity in various industries is SS304 Woven Wire Mesh. This versatile material is known for its durability, strength, and resistance to corrosion, making it an ideal choice for a wide range of applications.

The SS304 Woven Wire Mesh is made from high-quality stainless steel, specifically SS304 grade, which is renowned for its excellent corrosion resistance and strength. This makes it an ideal material for applications that require durability and reliability, such as filtration, sieving, and screening. With its sturdy construction and fine mesh openings, the SS304 Woven Wire Mesh is capable of withstanding high temperatures, heavy loads, and aggressive chemicals, making it suitable for use in demanding environments.

One of the key advantages of SS304 Woven Wire Mesh is its versatility. Its fine mesh openings and smooth surface make it an ideal material for filtration and sieving applications. It can be used to filter and separate particles of various sizes, making it an essential component in industries such as food and beverage, pharmaceuticals, and chemical processing. Additionally, the SS304 Woven Wire Mesh can be used for architectural and decorative purposes, thanks to its attractive appearance and durable construction.

The SS304 Woven Wire Mesh is also an excellent choice for security and safety applications. Its robust construction and high tensile strength make it an ideal material for fencing, guarding, and protective barriers. It can be used to create secure enclosures for industrial facilities, commercial properties, and public spaces, providing a reliable solution for perimeter security and access control.

In addition to its strength and durability, the SS304 Woven Wire Mesh is also known for its ease of installation and maintenance. Its flexible and lightweight nature allows for easy handling and installation, reducing the time and effort required for deployment. Furthermore, its smooth surface and resistance to corrosion make it easy to clean and maintain, ensuring long-lasting performance and reliability.

The company {}, a leading manufacturer of SS304 Woven Wire Mesh, is dedicated to providing high-quality solutions for various industries and applications. With a wealth of experience and expertise in stainless steel processing and fabrication, they have established themselves as a trusted supplier of premium woven wire mesh products. Their SS304 Woven Wire Mesh is manufactured using advanced weaving technologies and stringent quality control measures, ensuring consistent quality and performance.

As a customer-centric company, {} is committed to meeting the unique needs and specifications of their clients. They offer a wide range of customization options for their SS304 Woven Wire Mesh, including different mesh sizes, wire diameters, and surface finishes. This flexibility allows their customers to find the perfect solution for their specific requirements, ensuring that they receive a product that meets their expectations and delivers exceptional value.

With its unmatched strength, durability, and versatility, SS304 Woven Wire Mesh is proving to be an indispensable material for a wide range of applications. Whether it's for filtration, security, or decorative purposes, this reliable material offers a practical and cost-effective solution for various industries and businesses. With the expertise and dedication of companies like {}, the future of SS304 Woven Wire Mesh looks bright, promising continued innovation and excellence in the years to come.

Company News & Blog

Rectangular Bar Hexagonal Grid Grating for Concrete Framing

McNichols is a company that has been in existence for over 60 years. They specialize in the supply of industrial metal products to various industries in different parts of the world. The company prides itself on providing its clients with superior quality products that meet the highest standards in the industry. This has made the company one of the leading providers of industrial metal products globally.The company's latest offering, the Clinched HEXMESH Grating, is a high-quality product made with rectangular bars that are clinched together in a hexagonal grid. This unique design provides excellent durability and strength, making this grating the go-to solution for various applications.One of the primary applications for this grating is within concrete walls, flooring, and refractory applications. Concrete is a popular building material due to its impressive strength and durability. However, concrete is prone to cracking and blistering, primarily when exposed to high temperatures or harsh environments. The Clinched HEXMESH Grating helps prevent these issues by providing reinforcement to the concrete structure. This results in a more durable and long-lasting building.The Clinched HEXMESH Grating is also ideal for use in industrial applications that require strong and durable walkways, platforms, and mezzanines. Its unique design allows for excellent drainage and ventilation, making it an ideal choice for outdoor industrial applications. The Clinched HEXMESH Grating can withstand heavy loads, making it perfect for heavy-duty industrial applications.McNichols has 19 locations across the United States, ensuring that their clients have easy access to their products. They have a team of experts who are dedicated to providing top-notch customer service and technical support to their clients. This team ensures that clients receive the right product for their specific needs and that they are installed correctly.The Clinched HEXMESH Grating is available in various sizes and specifications to accommodate different applications. McNichols ensures that all their products are of the highest quality, meeting the highest industry standards. They subject all their products to rigorous quality control checks to ensure that they meet these standards.Clients can contact McNichols' customer service team for a quote or more information on this grating. The team is always ready to provide clients with all the information they need to make informed decisions.In conclusion, McNichols continues to be a leader in the supply of industrial metal products, providing clients with superior quality products that meet the highest industry standards. Their latest offering, the Clinched HEXMESH Grating, is no exception. Its unique design provides excellent durability, making it ideal for various industrial applications. Clients can rely on McNichols to provide them with top-notch products and services that meet their specific needs.

Steel Grating Market Analysis: Key Insights and Industry Trends Revealed

Title: Advancement in Steel Grating Production for Improved Safety and DurabilityIntroduction:[Company Name], a renowned leader in the manufacturing of high-quality steel products, has recently made significant strides in its steel grating production. With a primary focus on safety and durability, the company has introduced innovative techniques to enhance the performance of steel gratings, catering to the ever-evolving needs of various industries and sectors. Through extensive research and development, [Company Name] has revolutionized the steel grating market, providing customers with reliable solutions for a wide range of applications.Body:1. Understanding Steel Grating:Steel grating is a versatile and extensively used construction material designed for superior strength, support, and ventilation purposes. It consists of a series of parallel and perpendicular metal bars, known as bearing bars, positioned at regular intervals to create a grid-like structure. Steel gratings are commonly employed in industrial plants, commercial buildings, bridge walkways, and various other infrastructure projects due to their robustness and versatility.2. Enhanced Safety Features:Recognizing the utmost importance of safety, [Company Name] has incorporated several enhancements in its steel grating production. These features aim to mitigate the risk of accidents and ensure the well-being of workers and pedestrians. By carefully optimizing the spacing between bearing bars, the steel gratings now offer a secure platform for walking and heavy equipment operation. Slip-resistant surfaces have also been integrated, providing additional grip in wet or oily conditions, making the gratings ideal for both indoor and outdoor environments.3. Durability and Longevity:[Company Name] acknowledges the need for long-lasting steel gratings that withstand harsh environmental conditions and heavy loads without compromising integrity. By utilizing advanced corrosion-resistant coatings and high-tensile strength materials, the company has significantly enhanced the durability and longevity of its steel gratings. These improvements ensure prolonged usage life while minimizing maintenance requirements and associated costs, making them an economical choice for businesses.4. Customization Options:As each project has unique requirements, [Company Name] offers extensive customization options for its steel grating products. Customers can choose from a variety of bar spacing, mesh sizes, surface textures, and materials to meet their specific needs. This flexibility allows for seamless integration into existing structures without compromising on functionality or aesthetics.5. Sustainable Manufacturing Practices:Environmental responsibility is at the forefront of [Company Name]'s core values. To reduce its carbon footprint, the company has implemented sustainable manufacturing practices throughout its steel grating production. Through meticulous material sourcing and waste management strategies, [Company Name] ensures minimal impact on the environment while maintaining exceptional product quality and performance.6. Industry Applications:The technologically advanced steel gratings produced by [Company Name] find diverse applications across numerous industries. Industrial and manufacturing plants widely utilize these gratings for flooring, shelves, and platforms due to their load-bearing capabilities and anti-slip properties. They are also extensively employed in water treatment plants, oil and gas refineries, and chemical facilities where exposure to corrosive substances is a concern. Additionally, steel gratings provide effective drainage solutions in parking lots, airports, and public areas, preventing water accumulation and minimizing the risk of accidents.Conclusion:With its remarkable advancements in steel grating production, [Company Name] is revolutionizing the safety and durability standards in the industry. The incorporation of enhanced safety features, customization options, and sustainable manufacturing practices ensures that [Company Name] steel gratings meet the diverse requirements of various sectors. As a market leader, [Company Name] continues to innovate and provide reliable solutions that offer immense value to its customers, contributing to a safer and more sustainable future for all.

Top Suppliers of Access Control Gates and Woven Wire Mesh - Unbiased Customer Reviews & Product Information

Title: Knitted Wire Mesh: A Trusted Supplier of Versatile Wire Mesh SolutionsIntroduction:In today's dynamic world, companies are constantly seeking efficient and reliable solutions to secure their premises while balancing aesthetics and functionality. Knitted Wire Mesh, a renowned industry player, has emerged as a trusted supplier of high-quality wire mesh products for various applications. With a diverse range of wire mesh options, including access control gates and woven wire mesh, Knitted Wire Mesh has earned a reputation for unparalleled customer satisfaction and innovative solutions.Product Offerings:Knitted Wire Mesh offers an extensive range of wire mesh products tailored to meet the diverse needs of its customers. Their vast selection includes access control gates, woven wire mesh, and much more. The company's commitment to excellence is reflected in the quality of its products, which are manufactured using state-of-the-art technology and premium materials.Access Control Gates:One of the standout offerings from Knitted Wire Mesh is their access control gates. Designed to provide exceptional security without compromising on aesthetics, these gates offer a convenient and reliable solution for controlling access to various premises. Knitted Wire Mesh prides itself on delivering custom-made gates that seamlessly integrate into different architectural designs.With safety at the core of their design, Knitted Wire Mesh access control gates employ innovative mechanisms such as advanced locking systems, biometric scanners, and CCTV integration. These features ensure that only authorized personnel gain access while deterring unauthorized individuals from entering restricted areas.Woven Wire Mesh:Another flagship product offered by Knitted Wire Mesh is their woven wire mesh. This versatile solution finds extensive use in diverse applications, including industrial settings, agriculture, architecture, and interior design. Woven wire mesh is highly sought after for its ability to provide robust security, efficient filtration, and decorative enhancement.Knitted Wire Mesh's woven wire mesh products are manufactured with precision, ensuring exceptional strength, durability, and resistance to wear and tear. With various customization options available, customers can choose from an array of patterns, finishes, and materials to achieve their desired aesthetic appeal and performance characteristics.Customer Experience:The success of Knitted Wire Mesh can be attributed, in large part, to its commitment to customer satisfaction. The company places great emphasis on establishing strong relationships with its clientele. Their genuine customer reviews speak volumes about the exceptional quality of their products and the professionalism of their staff.Knitted Wire Mesh excels in providing detailed product and service information, assisting customers in making informed decisions. The technical expertise of their team ensures accurate product recommendations suitable for any specific requirements. Furthermore, the company's prompt delivery and comprehensive after-sales support contribute to a hassle-free experience for their valued customers.Conclusion:As businesses continue to prioritize robust security measures, Knitted Wire Mesh has emerged as a leader in providing high-quality wire mesh solutions. Their diverse product line, including access control gates and woven wire mesh, combined with their unwavering customer focus, has allowed them to establish a solid reputation in the industry.Embracing cutting-edge technology and maintaining a commitment to the highest standards of quality, Knitted Wire Mesh is well-positioned to serve the evolving needs of various sectors. Whether it be for industrial applications, architectural design, or enhancing security, customers can trust Knitted Wire Mesh to deliver innovative and dependable wire mesh products.

Explore a Wide Range of High-Quality Twin Loop Wire Binding Machines & Systems

If binding wire is a part of your business, then you should know that selecting the right binding machine can make all the difference. However, with the wide variety of options available, choosing the right one can be overwhelming. To help you make an informed choice, we’ve put together this comprehensive guide to selecting the right wire binding machines.Wire binding, also known as Twin Loop Binding or Double Loop Binding, is a popular binding method that utilises a double loop wire that is inserted through the punched holes in the pages to hold them together. Wire binding is a versatile binding style, as it is available in a wide variety of sizes and can handle both small and large documents.When choosing a wire binding machine, there are several factors to consider, including size, capacity, and durability.Size: The size of your wire binding machine should match your specific needs. Smaller machines are designed for home offices or small businesses with low volume binding requirements. However, if you plan on binding a large number of documents, then you will need a larger machine.Capacity: The capacity of your wire binding machine determines how many sheets of paper it can bind at one time. The higher the capacity, the more sheets it can handle. If you frequently bind large documents, then you should choose a machine with a high capacity to save time.Durability: The durability of your wire binding machine is another important consideration. You want a machine that is built to last and can handle the wear and tear of daily use. A sturdy machine can save you money in the long run as it won't need to be replaced as often.In addition to these factors, you should also consider the pitch and wire size for your wire binding machine.Pitch: Pitch refers to the distance between the holes punched in the pages. A 3:1 pitch has three holes per inch, while a 2:1 pitch has two holes per inch. If you’re binding a large document, a 2:1 pitch may be the best option since it can handle more sheets.Wire Size: The wire size you choose will depend on the number of pages you plan to bind. A larger wire size can handle more pages, but it may not be the best option if you don't need to bind large documents.When it comes to choosing a wire binding machine, there are several great options available to you.To begin with, you can choose from a range of manual and electric wire binding machines. Manual machines are more affordable and are perfect for low-volume binding. On the other hand, electric machines are an excellent choice for high volume binding as they can bind documents quickly and efficiently.Another option is the modular system. With a modular system, you can build your binding machine to suit your needs. You can choose from a range of modules, including punching modules, closing modules, and binding modules, to create a customised machine that meets your specific needs.Overall, the wire binding machine you choose will depend on your specific needs and requirements. Whether you opt for a manual or electric machine, size, capacity, and durability should be the primary considerations. Be sure to choose a machine that is built to last and that can handle your daily work requirements.In conclusion, selecting the right wire binding machine is critical if you want to efficiently and effectively bind your documents. There is a wide variety of options available, and choosing the right one can make all the difference. With the information in this guide, you can make an informed decision and choose a wire binding machine that best suits your needs.

Top Benefits of Steel Bar Grating You Should Know

Steel bar grating is a crucial component in various industries, providing essential structural support and safety features. It is commonly used in flooring, walkways, ramps, and other platforms where a durable and reliable surface is necessary. One company that has been at the forefront of providing high-quality steel bar grating solutions is {}.{} is a leading manufacturer of steel bar grating, offering a wide range of products that meet the needs of diverse industries. With a strong focus on quality and customer satisfaction, the company has established itself as a trusted name in the field of steel bar grating.The steel bar grating produced by {} is known for its durability, strength, and versatility. It is designed to withstand heavy loads and harsh environmental conditions, making it ideal for use in industrial settings, commercial facilities, and public infrastructure. Whether it's for a new construction project or a renovation, {} provides the right steel bar grating solutions to meet the specific requirements of its clients.In addition to its high-quality products, {} also takes pride in its commitment to innovation and technological advancement. The company continuously invests in research and development to improve its manufacturing processes and develop new products that align with the evolving needs of the industry. This dedication to innovation has allowed {} to stay ahead of the competition and maintain its position as a leader in the steel bar grating market.Furthermore, {} understands the importance of sustainability and environmental responsibility. The company adheres to strict standards and practices that minimize its environmental impact and promote eco-friendly manufacturing processes. By adopting sustainable practices, {} not only contributes to a healthier planet but also provides its customers with greener solutions for their projects.Another key aspect of {}'s success is its unwavering commitment to customer satisfaction. The company takes a proactive approach to understand the unique needs of its clients and works closely with them to deliver customized steel bar grating solutions that exceed their expectations. Whether it's providing expert advice, ensuring timely delivery, or offering exceptional customer support, {} goes the extra mile to ensure a positive experience for its clients.To further solidify its position in the market, {} has established a strong distribution network that enables it to reach clients across different regions. This global reach, combined with its reputation for quality and reliability, has earned {} the trust of numerous companies and organizations around the world.In conclusion, steel bar grating plays a vital role in various industries, and {} has been a driving force behind the advancement and application of this essential product. With its focus on quality, innovation, sustainability, and customer satisfaction, {} continues to be a frontrunner in the steel bar grating industry, providing top-notch solutions that meet the needs of its diverse clientele. As the company looks to the future, it remains committed to pushing the boundaries of what is possible in steel bar grating technology and setting new standards for the industry.

How Copper Wire Mesh can be Used for Different Applications

Copper Wire Mesh – A Game Changer for Modern IndustriesThe world of technology and innovation is ever-changing, and businesses are constantly looking for ways to adapt to the changing environment to remain competitive. In today's fast-paced world, industries need sophisticated solutions to improve their products' quality, performance, and durability. Copper wire mesh is one of the game-changers in the market. With its unique properties, this material has revolutionized modern industries, offering a wide range of engineering and technological applications.Copper wire mesh is essentially a woven wire cloth produced from high-quality copper wires. This mesh has a unique structure that provides a multitude of benefits that make it suitable for various industrial, architectural, and technological applications. The mesh's advantages include corrosion and rust resistance, high electrical conductivity, thermal stability, and significant filtration properties.Industries have been using Copper wire mesh for many years, and it continues to be a go-to material for many companies, especially in the electrical and electronic industries. Electrical conductivity is one of the most critical properties of copper wire mesh, making it useful in conducting electrical signals without any resistance. This quality has made copper wire mesh ideal for manufacturing electrical components and products such as transformers, motors, generators, and printed circuit boards (PCBs).The filtration properties of the copper wire mesh make it an ideal material for various industrial applications. Copper wire mesh is capable of filtering small particles and substances from the gases and liquids passing through it, making it suitable for use in chemical processing, refining, and petrochemical plants. Additionally, the mesh's ability to withstand high temperatures and corrosion resistance makes it ideal for use in harsh environments such as offshore oil rigs.Another significant advantage of copper wire mesh is its thermal stability. The relatively high melting point of copper wire mesh makes it ideal for use in high-temperature applications such as ovens, furnaces, kilns, and other heat treatment applications. Copper wire mesh can withstand high temperatures and is an excellent conductor of heat, making it an ideal material for heat exchangers and other applications where thermal conductivity is essential.Several companies around the world have made significant investments in researching and developing innovative copper wire mesh solutions. One such company that stands out is {Company Name}. The company has been in the copper wire mesh manufacturing industry for over 30 years and has become a leading global manufacturer and supplier of copper wire mesh.{Company Name} prides itself on developing exceptional solutions that meet their clients' unique needs, providing them with superior copper wire mesh solutions. The company's success lies in its unwavering commitment to producing high-quality copper wire mesh products that exceed customer satisfaction. Their team of highly skilled and experienced professionals ensures that every product that leaves their warehouse meets the highest standards of quality and consistency.The company offers an extensive range of copper wire mesh products, including woven wire mesh and expanded metal mesh, suitable for various applications. Their unique designs and exceptional engineering capabilities have made them the go-to supplier for many industries in the Middle East, Europe, the Americas, and Asia.{Company Name} has invested millions of dollars in research and development to create unique and innovative copper wire mesh solutions. Their range of products includes precision woven wire mesh, sintered wire mesh, perforated metal, and the world-renowned Dutch weave mesh. The company combines high-quality materials and sophisticated technology to manufacture these products, providing superior filtration properties, and ensuring that the meshes can withstand harsh weather conditions without corroding.In conclusion, Copper wire mesh is a game-changer for modern industries, providing a wide range of benefits that make it a suitable material for various engineering and technological applications. The properties of the copper wire mesh, including electrical conductivity, thermal stability, corrosion resistance, and filtration properties, make it an ideal material for use in electrical and electronic industries, refineries, petrochemical plants, and offshore oil rigs. The commitment of companies such as {Company Name} to developing high-quality copper wire mesh products has resulted in exceptional solutions that exceed customer expectations, ensuring that they remain competitive in their respective markets.

Woven Wire Mesh: Perfect Solution for Various Industrial ApplicationsWoven wire mesh is an important industrial product that plays a crucial role in filtering, sorting, and separation processes. These meshes are made up of woven wires that are interlocked at right angles, forming a strong and durable material. With their high-quality and customizable nature, woven wire meshes are used in various industrial applications, including polymer extrusion, filtration, and sieving.One of the most popular woven wire meshes is the SS304 Woven Wire Mesh, which is widely used in food processing, chemical, and pharmaceutical industries. The SS304 Woven Wire Mesh is made of high-quality stainless steel which provides high corrosion resistance, strength, and excellent heat resistance. Furthermore, the SS304 Woven Wire Mesh is known for its easy-to-clean properties and hygienic characteristics, making it suitable for food and medical applications.At ANPING COUNTY DONGJIE WIREMESH PRODUCTS CO., LTD. (need remove brand name), we specialize in manufacturing and supplying high-quality SS304 Woven Wire Meshes. Our factory wholesale plain weave stainless steel woven wire mesh cloth is one of the most sought-after products in the market due to its superior quality and durability.Our SS304 Woven Wire Meshes are made from premium quality stainless steel that is woven using advanced technology to ensure high precision and accuracy. We offer a wide range of mesh sizes and wire diameters to suit a wide range of applications.One of the most common applications of our SS304 Woven Wire Meshes is in polymer extruder screens. These screens are used to prevent impurities from entering the extruder, ensuring product quality and consistency. Our high-quality SS304 Woven Wire Meshes are perfect for use in such extruder screens, as they offer superior strength, durability and wear resistance.Our stainless steel square metal woven sieving screen filter wire mesh is another product that is in high demand. These meshes are used in the filtration and separation of solid and liquid products in various industries such as chemical, food processing, and pharmaceutical.At ANPING COUNTY DONGJIE WIREMESH PRODUCTS CO., LTD. (need remove brand name), we pride ourselves on providing our customers with high-quality products that meet their specific needs. Our expertise in the manufacturing of woven wire meshes has helped us to become one of the leading suppliers in the industry.In conclusion, SS304 Woven Wire Meshes are an essential industrial product that plays a crucial role in filtration, sieving, and separation processes. At ANPING COUNTY DONGJIE WIREMESH PRODUCTS CO., LTD. (need remove brand name), we specialize in manufacturing high-quality SS304 Woven Wire Meshes that are durable, hygienic, and customizable to meet specific customer requirements. Our commitment to quality and customer satisfaction has helped us to become one of the most trusted suppliers in the industry.

Essential Guide to Constructing a Durable Gabion Retaining Wall

Gabion Retaining Wall Technology is an innovative approach to constructing retaining structures. This technology has been widely embraced by various industries, including construction, civil engineering, and infrastructure development. It involves the use of wire baskets filled with locally sourced stones, to construct strong, sturdy, and aesthetically pleasing retaining walls. Gabion Retaining Walls are an efficient and cost-effective solution for slope stabilization and erosion control; they can be adapted to various terrains and can resist the forces of nature, including wind, water, and soil movement.According to the leading supplier and installer of gabion products, the technology has become popular due to its numerous advantages, including allowing for maximum stability even in areas of lateral pressure. The baskets are durable, corrosion-resistant, and can be adjusted to the required size and shape. They can also be filled with a variety of materials other than stone, including concrete, wood, and recycled materials, as long as they are durable and provide adequate support.Gabion Retaining Walls can be used for a variety of applications, such as in slope stabilization and erosion control, river and coastal protection, noise barriers, landscaping, and water management. Additionally, they are eco-friendly, easy to maintain, and can last for many years.The use of Gabion Retaining Walls in infrastructure development has led to significant cost savings due to the use of local, recycled materials, which are readily available and less expensive than other construction materials. This technology has also contributed to reduced environmental impact since it prevents soil erosion and provides habitats for different species of flora and fauna."Gabion Retaining Walls are a great alternative to conventional construction methods. Their strength, durability, and flexibility have made them an ideal solution for many applications, including slope stabilization and soil erosion," stated a spokesperson from the leading supplier and installer of gabion products. "Our company is proud to be at the forefront of the growth of this technology in the construction industry."The technology is gaining widespread acceptance in Africa, especially given the increasing demand for construction materials that align with sustainable environmental practices. The need for durable and cost-effective infrastructure development solutions can be attributed to the rapid population growth and urbanization in Africa. In addition to being easy to install and maintain, Gabion Retaining Walls can blend in with their natural surroundings, resulting in aesthetically pleasing and environmentally friendly structures.Gabion Retaining Walls technology is poised to revolutionize the construction industry in Africa and promote sustainable infrastructure development. With its numerous advantages, the technology is expected to gain market share and become one of the leading construction methods adopted. The adoption of Gabion Retaining Walls technology will contribute significantly to the development of infrastructure in Africa, while also promoting environmental conservation.In conclusion, Gabion Retaining Walls are an innovative, eco-friendly, and cost-effective construction solution. The technology has gained popularity worldwide due to its numerous advantages, including durability, flexibility, and easy maintenance. Infrastructure development in Africa is set to benefit significantly from this technology, which promotes environmental conservation and provides a sustainable solution to construction challenges. The growth of the Gabion Retaining Walls technology in Africa is set to revolutionize the construction industry and promote sustainable infrastructure development.

High Quality Binding Wire for Sale: Types and Uses

Unleashing Innovation: A New Milestone in Binding Wire TechnologyIn an era where innovation is the driving force behind every industry, the construction sector is no exception. The demand for stronger, more durable construction materials has pushed companies to explore new technologies. One such company, {}, has made great strides in revolutionizing the binding wire industry with the introduction of their groundbreaking new product.Binding wire is an essential component in the construction industry, used for securing steel bars and reinforcing concrete structures. Traditionally, binding wire has been manufactured using conventional techniques, resulting in limitations in strength and durability. However, {} has defied these limitations with their advanced manufacturing process, delivering a binding wire that is not only stronger and more resilient but also more sustainable.The company's new binding wire is the result of extensive research and development, utilizing state-of-the-art technology to enhance its properties. By incorporating cutting-edge materials and advanced production methods, {} has succeeded in creating a binding wire that surpasses industry standards in terms of strength, durability, and corrosion resistance.One of the key features of {}'s new binding wire is its high tensile strength, which significantly exceeds that of traditional binding wire. This increased strength not only provides greater security and stability to concrete structures but also allows for more efficient and cost-effective construction processes. In addition, the advanced manufacturing process ensures that the binding wire is more durable, offering a longer service life and reducing the need for frequent replacements.Moreover, {} has placed a strong emphasis on sustainability in the manufacturing of their new binding wire. By implementing eco-friendly production methods and using recyclable materials, the company has minimized the environmental impact of their product, aligning with the global push for sustainable construction practices.The impact of {}'s innovation in binding wire technology extends beyond just the construction industry. With the growing emphasis on sustainable and resilient infrastructure, the demand for stronger and more durable construction materials has never been higher. {}'s new binding wire is set to play a pivotal role in meeting this demand, offering a solution that not only enhances the performance of concrete structures but also contributes to the overall sustainability of construction projects.The introduction of {}'s advanced binding wire is a testament to the company's commitment to innovation and excellence. As a leading manufacturer in the construction materials industry, {} has continually pushed the boundaries of technology to deliver superior products that meet the evolving needs of the market. With their new binding wire, the company has once again demonstrated their ability to lead the way in driving innovation and shaping the future of construction.In conclusion, {}'s new binding wire represents a significant milestone in the evolution of construction materials. Its superior strength, durability, and sustainability set a new standard for binding wire technology, offering a compelling solution for the construction industry's evolving needs. As the demand for stronger, more resilient infrastructure continues to rise, {}'s innovative binding wire is poised to make a lasting impact on the industry, reshaping the way concrete structures are reinforced and constructed.

Discover the Latest Updates on Steel Bar Grating in the News

Steel Bar Grating: A Versatile Solution for Industrial ApplicationsIn today's rapidly developing industrial landscape, the importance of reliable and versatile materials cannot be underestimated. Steel bar grating, an essential component widely used in various industries, stands out as a prime example of a durable and efficient solution. With its remarkable strength, resilience, and versatility, steel bar grating has become a go-to choice for many industrial applications.Steel bar grating refers to a grating product comprised of parallel steel bars aligned and fixed together at perpendicular intersections. This fabrication technique creates a strong and rigid structure capable of supporting heavy loads while allowing for the passage of air, light, and various liquids. The bars are often constructed with diamond-shaped openings, known as diamond mesh, providing additional grip and safety.One of the key advantages of steel bar grating is its superior strength. Made from robust carbon steel or stainless steel, it can withstand immense pressure, making it ideal for industrial environments. Whether it's a factory floor with heavy machinery or a construction site handling massive loads, steel bar grating offers unmatched durability, enabling safe operations and minimizing the risk of accidents.In addition to its strength, steel bar grating also boasts excellent corrosion resistance. Certain industries, such as chemical processing or offshore drilling, expose materials to highly corrosive substances, which can degrade lesser materials over time. However, steel bar grating's corrosion-resistant properties ensure its longevity even in the harshest environments. This makes it a cost-effective solution, as it reduces the need for frequent replacements or repairs.Moreover, steel bar grating offers unparalleled versatility. With a variety of bar designs, including serrated, plain, or I-bars, it can be customized to meet the specific needs of different industries. For instance, serrated bars provide additional grip, preventing slips and falls in areas prone to moisture or oil. Conversely, smooth or plain bars are perfect for pedestrian walkways or platforms where slip resistance is not a primary concern. This adaptability makes steel bar grating suitable for a wide range of applications, from flooring and stair treads to drainage covers and shelving.Furthermore, the installation process of steel bar grating is relatively simple. It can be customized to fit any shape or size required by a particular project, ensuring a seamless integration into the existing infrastructure. The interlocking system of bars provides stability and strength, guaranteeing a secure platform for workers and machinery. Moreover, steel bar grating can be easily lifted, moved, or adjusted as needed, making it a practical choice for evolving industrial spaces.One company at the forefront of manufacturing high-quality steel bar grating is {}. With years of experience and a commitment to innovation, they have established themselves as a trusted supplier in the industry. Their steel bar grating products not only meet rigorous international standards, but they also offer a wide range of options to suit different project requirements.Company {} utilizes state-of-the-art technology and modern manufacturing techniques to ensure the production of precision-engineered grating products. Their highly skilled team of professionals is dedicated to delivering superior quality and outstanding performance in every steel bar grating they manufacture.Additionally, the company places a strong emphasis on sustainability and environmental responsibility. They adhere to strict eco-friendly practices and use raw materials from sustainable sources, minimizing their carbon footprint. By choosing their steel bar grating products, customers can contribute to a greener and more sustainable industrial future.In conclusion, steel bar grating serves as an essential solution for various industrial applications. Its remarkable strength, corrosion resistance, and adaptability make it a reliable choice for companies operating in different sectors. With companies like {}, dedicated to manufacturing high-quality and sustainable steel bar grating products, the future of industrial infrastructure is secure, providing a safe and efficient working environment for the workforce.